Hammar 151

36 or 42 tonnes Safe Working Load, tare weight from 9,4 tonnes.

- Versatile positioning of support legs

- The highest lifting capacity

- Advanced lifting options

- All-round model

- Trailer mounted

36 or 42 tonnes lifting capacity

36 or 42 tonnes Safe working load, tested with up to 56 tonnes. Strongest Sideloader in the world.

Advanced lifting options

The Hammar 151 can be equipped with a number of advanced lifting options, such as high cube stacking, container spreader and extendable cranes.

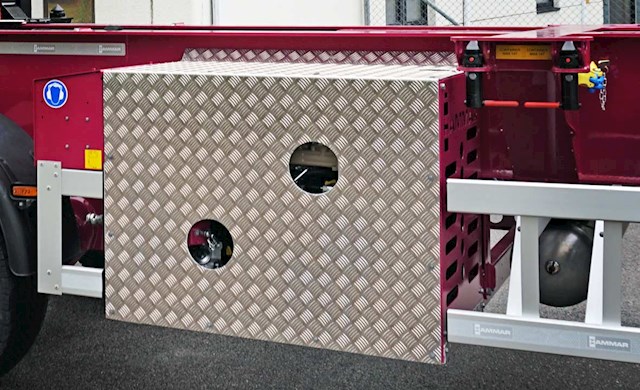

Versatile support legs

The support legs are extending and tilting, making their positioning very versatile. An excellent quality when you have a wide range of different situations you are operating in.

Trailer or truck mounted

The Hammar 151 cranes can be mounted on a number of different trailer models or directly on a truck chassis.