Hammar 110

36 tonnes Safe Working Load, tare weight from 8,4 tonnes.

- Versatile double-action support legs

- Transfer specialist, low tare weight

- High efficiency, advanced lifting options

- Low ground pressure & high stability

- Trailer or truck mounted

36 tonnes lifting capacity

With 36 tonnes Safe working load the Hammar 110 can easily handle fully loaded containers.

Advanced lifting options

The Hammar 110 can be equipped with a number of advanced lifting options, such as a container spreader and extendable cranes.

StepOver mode

One of two stabilizer modes available on the 110 model. Provides fast, safe and easy transferring to/from another chassis and gives high stability with extra low ground pressure.

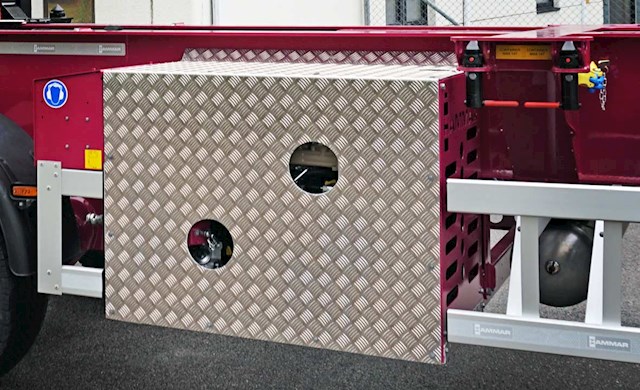

Sledge mode

One of two stabilizer modes available on the 110 model, proving faster ground level handling and requires less space to operate.

Low tare weight

The Hammar 110 is the lighest Sideloader in its class, with a tare weight from 8,4 tonnes with 3-axles and 20'-40' capacity.

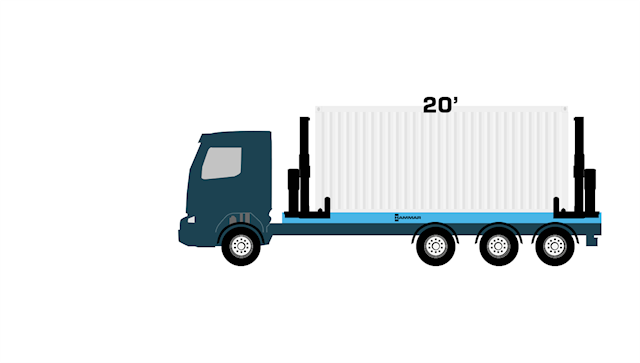

Trailer or Truckmounted

The Hammar 110 cranes can be mounted on a number of different trailer models or directly on a truck chassis.