Hammar 130

16-tonnes Safe Working Load, tare weight from 7.4 tonnes.

- Versatile positioning of support legs

- Fast handling of 1 of 2 individual 20’

- Optional collapsible crane with underslung leg

- 3-crane solution

3-crane solution

The Hammar 130 is mainly used as a 3-crane solution for more efficient and individual handling of 20' containers, but can also be built as a mid-range 2-crane Sideloader.

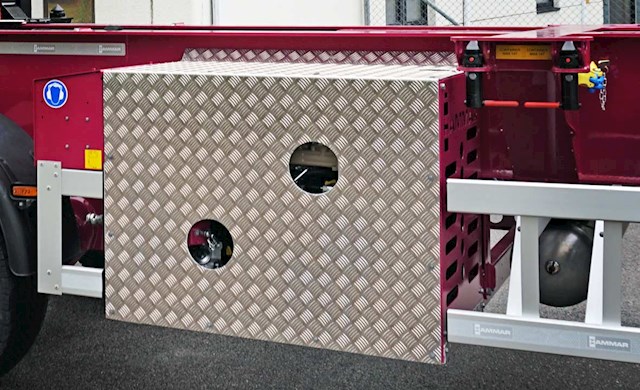

Versatile support leg option

The Hammar 130 can be built with two different support legs.

Underslung leg with low working height

The underslung leg has a very low working height, allowing you to place it under a companion chassis or rail wagon during transfer operations.

Collapsible crane

The underslung support leg has a collapsible crane. Mounted in the middle of a 3-crane solution, it allows 40' container handling. Mounted back you can open a container while it's still on the chassis

Truck or trailermounted

The Hammar 130 Sideloader can be mounted both on a semi-trailer and directly on a truck frame.

16 tonnes lifting capacity

The Hammar 130 has 16 tonnes lifting capacity, and can handle empty containers or lightly loaded containers.