Hammar 160

36 tonnes Safe Working Load, tare weight from 7,5 tonnes.

- Extremely low tare weight

- Two support leg positions

- Compact design

- Fast and easy handling

- Trailer mounted

36 tonnes lifting capacity

With 36 tonnes Safe Working Load the Hammar 160 can easily handle fully loaded containers.

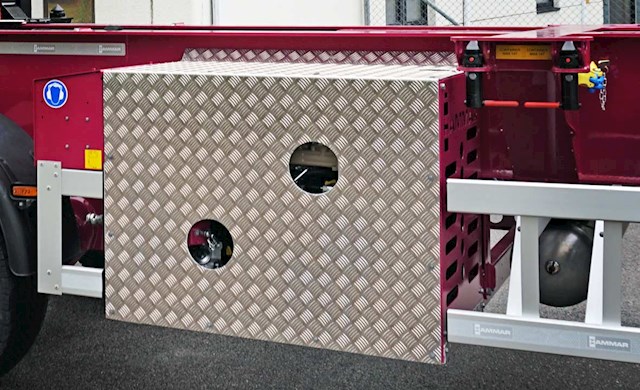

Compact and simple

The Hammar 160 is very easy to operate and has an the crane and support leg in line with eachother, making the overall design more compact.

Lightest Sidelifter on the market

The Hammar 160 is the lightest heavy duty Sidelifter on the market, with a tare weight starting at 7,5 tonnes with 3 axles and 20'-40 capacity.

Two support leg positions

The Hammar 160 support leg has two positions, one for ground level handling and one for transfering.

Trailer mounted

The Hammar 160 can be mounted on a number of different trailer models.