Hammar 119

36 or 45 tonnes Safe Working Load, tare weight from 8,7 tonnes.

- High versatility model with great transfer capabilities

- Two different types of support legs

- High Cube stacking, two containers high

36 or 45 tonnes Safe Working Load, tare weight from 8,7 tonnes.

The Hammar 119 is a highly adaptable Sideloader, combining the strengths of two different support leg types into a single, versatile solution. The model offers one of the best transfer capabilities as well as stacking capacity. With a lifting capacity of 36 or 45 tonnes (SWL) that can easily handle any loaded shipping container.

The front support leg, with its StepOver Mode, allows easy, fast and smooth container transfers from another chassis while also giving high stability for ground-to-ground lifts. Meanwhile, the rear tilting telescopic support leg provide added flexibility in its positioning. Coupled with its stacking capabilities, the Hammar 119 delivers a powerful combination of versatility and efficient transfer performance.

Lifting from/to ground level

The Hammar 119 Sideloader can safely and easily lift a fully loaded shipping container to/from the ground level. Deploying the stabilizers, attaching/removing the container hooks and lifting the container only takes approximately 3,5 minutes.

Transfer from/to another chassis

During transfer operations, the front support leg extends over and next to the companion chassis without making contact, creating a “tunnel”. This saves time for trailer transfers, as they can move in or out of the lifting zone while the support legs are deployed. The rear support leg is typically placed behind the companion chassis but can also rest on top of many chassis models if needed. The Hammar 119 can also work well for transferring from railway wagons.

Stacking capacity

The Hammar 119 is equipped with stacking capability, allowing two High-Cube containers to be stacked at ground level. This can help save space, enable you to handle more varied tasks and offer a wider range of services.

Modes of operation

The front support leg has an additional 2 modes of operation. The Sledge Mode (see image) has a quicker deployment time and requires significantly less space, while the Dock Mode requires similar space but has more flexible positioning.

When buying a Hammar Sideloader you always get a high quality Hammar designed chassis, optimized and made for Sideloader operations. We have a number of models to fulfil our customers’ requirements, which are then adapted to suit local regulations and the customer’s needs.

Fixed Chassis, Sliding Cranes - 119 HS

The S-chassis is a fixed length, and has sliding cranes meaning it can handle multiple container sizes. It has a straight forward design and the lowest tare weight of all Hammar chassis. It is the most common model used world-wide. Also available with fixed cranes for single size containers upon request.

Telescopic chassis, Combination - 119 HC

The most common telescopic chassis is the C-chassis (Combination). It combines sliding cranes with a telescopic chassis, and has a low tare weight. The sliding cranes enable optimized weight distribution of your load. A telescopic chassis is a requirement in some countries for transporting 45' or longer containers on the road.

Telescopic chassis, Advanced - 119 HA

The A-chassis (Advanced) is a unique chassis from Hammar and, as the name suggests, the most advanced. It is made of three moving chassis parts and has sliding cranes. This makes it possible to optimise the weight distribution for both 2 and 3-axle trucks, as well as for different container sizes. It is also possible to make it shorter than a C-chassis in its shortest position (20’).

Contact us today!

Axle configurations

We offer different axle configurations to your Hammar chassis; different numbers of axles, optimized weight distribution and more. All conforming to local regulations and your needs.

Gooseneck chassis

Our trailer chassis models can be built as a gooseneck chassis. A gooseneck chassis is designed to transport 40'+ High Cube containers in countries with low overall height restrictions. Max 36 tonnes lifting capacity.

Road train options

A Hammar chassis can be built with a 5th wheel/turntable or a drawbar coupling for towing another semi-trailer or trailer behind. This allows you to have a road train that you can load and unload with the Sideloader.

Low bed chassis

A Hammar trailer chassis can be built as a low bed chassis, giving a significantly lower overall height when loaded. Excellent for extra high loads or other situations that restrict the height of the vehicle.

Choose what, when and how you can lift with your Hammar Sideloader.

2x20' capacity

A centre container beam with 4 twist locks is mounted. With the 2 twin-locks (joiners) included you can connect and lift 2 lightly loaded 20' containers simultaneously. Heavier can be transported.

Raise & Lower function

Allows the operator to adjust the height of the trailer when loading/unloading. Extremely useful when operating on uneven ground, or when transferring from/to a higher or lower companion chassis.

Dangerous goods

The Hammar is equipped and adapted for handling of dangerous goods according to local regulations.

Weighing equipment

The Hammar can be equipped with two different weighing systems; a load indicator system with an accuracy of ± 400 kg and/or a SOLAS certified scale with an accuracy down to ±50 with optional printer.

Composite foot plates

Two foot plates of recycled composite material. Placed under the support legs or trailer landing legs, they drastically reduce the ground pressure. Comes with storage brackets on the Hammarlift.

Adjustable container stops

Adjustable container stops allow for transport of over-wide containers, e.g. tank or pallet wide containers.

Underslung Leg

Replace one of the support legs to the extending underslung leg. Excellent when support positions are below a chassis, rail wagon or similar. Available for model 110, 130, 151, 155, 160, 195.

Make operations and maintenance smoother and more efficient

Automatic container twist locks

Automatic crane twist locks for more efficient operations and less room for human error. Connected to automatically open/close when the crane power is engaged/disengaged.

Central Lubrication System

Automated centralized lubrication system supplying all greasing points on the crane and trailer. Reduces maintenance time and costs, and increases the product life time.

Hammar Optical positioning equipment

“HOPE” - Optical sensors reading the position of a container next to the Sideloader when lining up, alerting with a green light when cranes are in correct position for lifting. Increases efficiency.

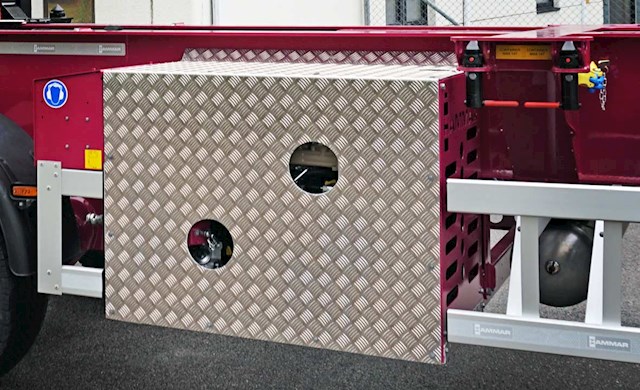

Toolbox

Alloy toolbox mounted on the non-lifting side of the Hammar Sideloader.

Lifting axle

Lifting one axle when driving with less load. Saves greatly on tyre wear. Lowers automatically when maximum legal load is reached on the other axles.

Increase safety for operations, the Sideloader and staff.

Radio remote control

Cordless radio remote for all Hammar functions. The operator can control the lifting from any position outside the hazard zone, increasing usability, efficiency and safety. Choose a 1 or 2 hand unit.

Hammar Safety+

A high quality, PLC based monitoring system that provides maximum safety. The mass and position of the load is continuously monitored. Includes a display that shows a number of useful variables.

Reverse camera/sensor

A camera or reverse sensor is installed in the rear of the Hammarlift. Increases efficiency, usability, safety and prevents damages.

Extra lights

Equip the Hammar Sideloader with extra LED lights for safer and more efficient operations with limited daylight. E.g. illumination of twist locks, extra reverse lights, or extra warning lights etc.

Reduce your tare weight, increase your payload and reduce wear and fuel consumption.

LightWeight Chassi

Optimized chassis structure and materials reduces the tare weight by 270-470 kgs depending on model. Available with alloy landing legs & carbon fender brackets. Available for chassis model S and C.

Aluminium rims

Aluminium rims reduces tare weight by 100-200 kg, while giving better heat distrubution, longer lifetime for tyres, brakes etc. and lowered fuel consumption. Gives a sleek and polished finish.

Personalize the look and style of your Hammar Sideloader. Your advertising on the road.

Painting options

Choose from a number of painting options. Colors of chassis and cranes. What type of paint, Hammar standard, metallic, clear coating or with zinc primer.

Aluminium rims

Aluminium rims gives a sleek and polished finish. Also reduces tare weight by 100-200 kg, while giving heat distrubution, longer life time for tyres, brakes etc. and lowered fuel consumption.

Stainless steel light bar

A high polished stainless steel light bar, with round LED lights. Gives a sleek and high-end look.

Advertisement plate

Personalize your Hammar with advertisement plates mounted on the sideguards or at the back crane of the 195 model. Choose color, graphics, text etc according to your needs.

Mudguards

Choose from standard mud guards and full width mud guards. Available with custom prints as option.

Choose how to power your Hammarlift.

Truck Hydraulics

Mount or use an existing hydraulic pump & power take-off on your truck and use the truck to power the Hammar. Significantly less tare weight and maintenance costs compared to a power pack.

Diesel Power Pack

Power the Hammar by mounting a separate engine on the chassis. Makes the unit powered independently of any truck.

Electric Power Pack

Electric power with zero emmision, lower operating costs and lower noise levels. Can be charged by the truck while driving and by plug-in.

Operator training

At Hammar, our goal is to give each and every operator a thorough training of our machines in order to operate them in a safe and efficient manner, all to minimize the risk of personal injuries and machine damage.

Financing solutions

Hammar, through our financial partner, offers a wide range of financial solutions to cover your needs. With a professional team we can recommend the right financial product for you, optimised to the local tax and laws for your area

Trade in your used Hammar

Hammar offers to trade in your old Hammar Sideloader when buying a new. With expert industry knowledge we will give you a professional evaluation of your Sideloader and a price to match.