Hammar 130

16-tonnes Safe Working Load

- Versatile positioning of support legs

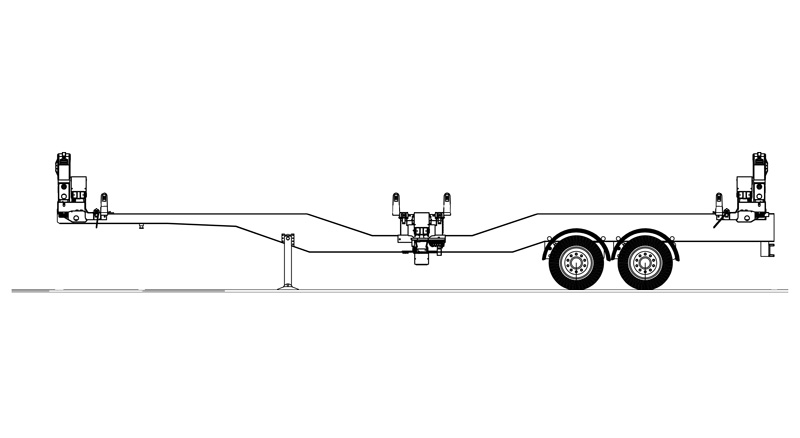

- Fast handling of 1 of 2 individual 20’

- Has a collapsible crane in the center of the chassis for 40' handling

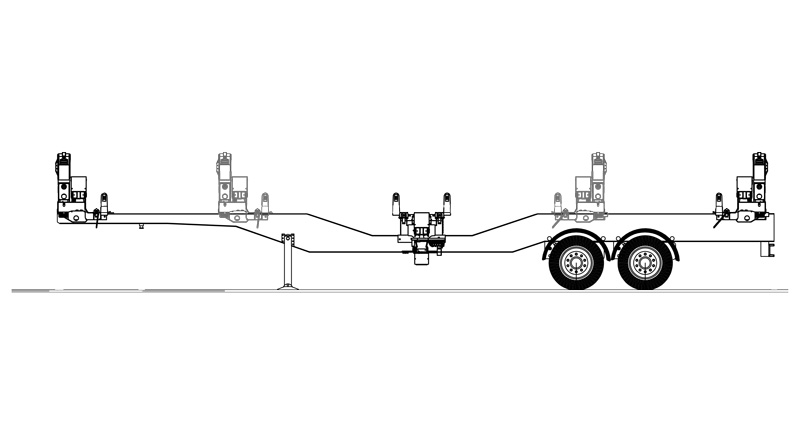

3-crane solution

The Hammar 130 is a 3-crane Sideloader solution for more efficient and individual handling of 20' containers

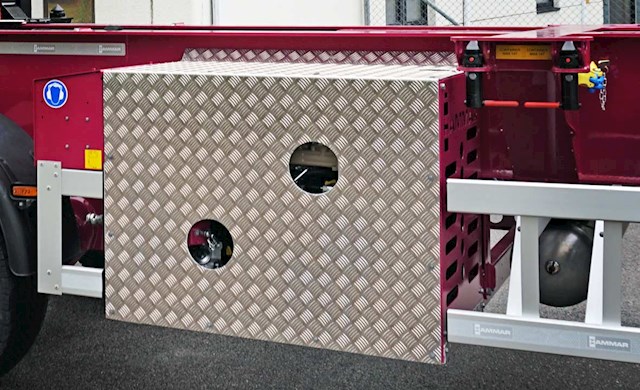

Versatile support leg option

The Hammar 130 can be built with two different support legs.

Underslung leg with low working height

The underslung leg has a very low working height, allowing you to place it under a companion chassis or rail wagon during transfer operations.

Collapsible crane

The underslung support leg has a collapsible crane. Mounted in the middle of the chassis, it allows 40' container handling.

16 tonnes lifting capacity

The Hammar 130 has 16 tonnes lifting capacity, and can handle empty containers or lightly loaded containers.